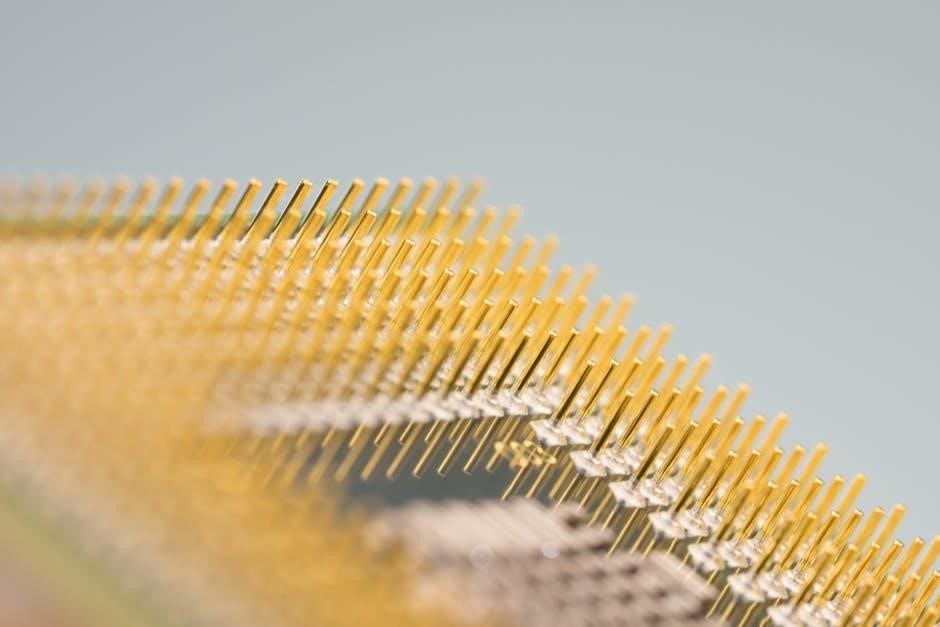

guide pin

Summary

Discover high-quality guide pins for precise machinery alignment. Explore durable solutions for your industrial needs.

Guide pins are essential components used to ensure precise alignment and positioning in various mechanical and manufacturing processes. They play a crucial role in maintaining accuracy and stability, making them indispensable in industries like CNC machining, aerospace, and automotive manufacturing. Their primary function is to guide parts or tools into correct positions, preventing misalignment and ensuring smooth operation. Available in different types and materials, guide pins are tailored to meet specific application requirements, ensuring optimal performance and reliability.

1.1 Definition and Purpose

Guide pins are cylindrical components used to align and position parts or tools accurately. Their primary purpose is to ensure precise fitting and proper orientation, minimizing errors in assembly and manufacturing. By guiding components into correct positions, they enhance operational efficiency and reduce the risk of misalignment, making them critical for maintaining production quality and consistency.

1.2 Importance in Engineering and Manufacturing

Guide pins are vital in engineering and manufacturing for ensuring precision and consistency. They minimize alignment errors, reduce production downtime, and enhance overall quality. By maintaining accurate positioning, guide pins contribute to efficient workflows and cost reduction. Their role is critical in achieving high-precision outcomes, making them indispensable in modern industrial applications.

Types of Guide Pins

Guide pins are categorized into standard, precision, and self-aligning types, each designed for specific applications requiring varying levels of accuracy and adaptability in mechanical systems.

2.1 Standard Guide Pins

Standard guide pins are commonly used in manufacturing for aligning parts and tools. Made from durable materials like steel, they offer reliable performance in various applications. Their simple design ensures cost-effectiveness and ease of use, making them ideal for general-purpose alignment tasks in jig fixtures and similar setups.

2.2 Precision Guide Pins

Precision guide pins are designed for high-accuracy applications, offering tight tolerances and minimal clearance. Made from advanced materials, they ensure consistent alignment in critical tasks. Their polished surfaces and precise diameters reduce wear and enhance performance, making them ideal for industries requiring extreme precision, such as aerospace and high-precision manufacturing.

2.3 Self Aligning Guide Pins

Self-aligning guide pins are designed with spring-loaded mechanisms or tapered ends, enabling automatic correction of minor misalignments. These pins accommodate angular deviations and reduce installation complexity, making them ideal for applications requiring quick setup and high tolerance. They are widely used in industries like automotive and electronics, where precise, efficient alignment is critical.

Materials Used for Guide Pins

Guide pins are typically made from high-quality materials such as steel and ceramic. Steel offers durability and strength, while ceramic provides excellent corrosion resistance and thermal stability, ensuring longevity and precision in various applications.

3.1 Steel Guide Pins

Steel guide pins are widely used due to their exceptional durability and strength. They resist wear and tear effectively, making them ideal for high-precision applications. Hardened steel variants offer even greater resistance to deformation, ensuring consistent performance over time. Their reliability and versatility make them a popular choice in manufacturing and CNC machining processes.

3.2 Ceramic Guide Pins

Ceramic guide pins are highly durable and resistant to wear, making them ideal for high-temperature and corrosive environments. Their hardness ensures minimal deformation, and they are lightweight compared to steel. Often used in aerospace and precision engineering, ceramic pins provide excellent performance in applications requiring chemical resistance and thermal stability, enhancing overall operational reliability.

3.4 Hardened Steel Guide Pins

Hardened steel guide pins offer exceptional strength and durability, making them ideal for heavy-duty applications. Their high hardness level resists wear and deformation, ensuring precise alignment over time. Commonly used in industrial machinery and automotive manufacturing, these pins provide long-lasting performance in demanding environments, reducing maintenance needs and enhancing operational efficiency significantly.

Installation and Alignment

Proper installation and alignment of guide pins are critical for ensuring precise positioning and functionality. Techniques involve using calipers and alignment jigs to achieve accurate placement and prevent errors.

4.1 Proper Installation Techniques

Proper installation of guide pins requires precision to ensure accurate alignment. Use calipers to measure and align the pin with the mating hole. Secure the pin using recommended tools, ensuring it is flush with the surface. Apply gentle force to avoid damage. Proper alignment prevents wear and ensures smooth operation, extending the lifespan of the guide pin.

4.2 Tools Required for Alignment

Calipers, dial indicators, and mounting jigs are essential tools for aligning guide pins. Calipers measure pin diameter and hole alignment, while dial indicators check surface flatness. Use a wrench or screwdriver for secure fastening. Proper tool selection ensures accurate alignment, minimizing errors and extending guide pin longevity. Always handle tools with care to avoid pin damage.

4.3 Common Mistakes to Avoid

Common mistakes include improper alignment, over-tightening, and using incorrect tools. Misalignment can cause wear, while overtightening may damage pins or surrounding material. Using wrong tools risks pin deformation. Ensure proper training, follow torque specifications, and regularly inspect pins to avoid these errors, ensuring longevity and optimal performance in critical applications.

Applications of Guide Pins

Guide pins are widely used in CNC machining, aerospace, automotive, and consumer electronics. They ensure precise alignment in manufacturing processes, facilitating accurate assembly and reducing errors. Their versatility makes them essential for maintaining efficiency and quality across various industries, ensuring components fit together flawlessly.

5.1 Use in CNC Machining

In CNC machining, guide pins are crucial for ensuring precise alignment of workpieces and tools. They minimize errors by maintaining consistent positioning, enabling accurate drilling, milling, and cutting. This enhances overall production quality, reduces material waste, and increases operational efficiency, making guide pins indispensable in high-precision manufacturing environments where consistency is key to success.

5.2 Role in Aerospace Engineering

Guide pins are critical in aerospace engineering for ensuring precise alignment and assembly of complex aircraft and spacecraft components. They enable accurate fitting of parts, reducing assembly errors and enhancing structural integrity. Their high precision and durability make them essential for maintaining safety and performance in demanding aerospace applications, where even minor misalignments can have significant consequences.

5.3 Application in Automotive Industry

Guide pins are extensively used in the automotive industry to ensure precise alignment during vehicle manufacturing and assembly. They facilitate accurate fitting of components such as engines, chassis, and body panels, minimizing assembly errors. Their use enhances production efficiency, reduces defects, and ensures consistent quality in high-volume automotive manufacturing processes, contributing to overall vehicle reliability and performance.

5.4 Use in Consumer Electronics

Guide pins are integral in consumer electronics manufacturing, ensuring precise alignment of components like circuit boards, displays, and casings. Their use in assembly lines prevents misalignment, reducing production errors and enhancing device reliability. This ensures seamless functionality and durability in products such as smartphones, tablets, and laptops, meeting the demand for high-quality electronics.

Advantages of Using Guide Pins

Guide pins enhance manufacturing efficiency by ensuring precise alignment, reducing errors, and speeding up production processes. They improve overall accuracy and consistency, making them a vital tool in modern industries.

6.1 Improved Accuracy

Guide pins are crucial for achieving precise alignment in manufacturing processes. They ensure components fit together accurately, reducing errors and inconsistencies. By maintaining exact positioning, guide pins enhance the quality of finished products, making them indispensable in industries requiring high precision and reliability.

6.2 Enhanced Precision

Guide pins significantly enhance precision by ensuring components fit together with minimal tolerance deviation. Their rigid design minimizes vibration and deflection, allowing for consistent and repeatable alignment. This level of precision is critical in high-accuracy applications, such as CNC machining and aerospace engineering, where even slight misalignments can lead to costly errors or compromised product quality.

6.3 Reduced Production Time

Guide pins streamline production processes by eliminating trial-and-error positioning, reducing setup times, and enabling faster alignment of components. This results in quicker production cycles and increased throughput. By minimizing adjustments and ensuring repeatable accuracy, guide pins help manufacturers complete tasks efficiently, ultimately lowering production timelines and boosting overall manufacturing productivity.

Challenges and Limitations

Guide pins face challenges like wear and tear, high costs for precision models, and maintenance needs. These factors can impact production efficiency and component longevity over time.

7.1 Wear and Tear

Guide pins are prone to wear and tear due to constant friction and repetitive use. Over time, this can lead to misalignment and reduced precision. Factors like improper lubrication and harsh environments exacerbate wear. Regular inspection and replacement are crucial to maintain accuracy and prevent operational disruptions in manufacturing processes.

7.2 Cost Factors

Guide pins’ costs are influenced by material quality, manufacturing complexity, and precision requirements. High-grade steel or ceramic pins are more expensive due to their durability and performance. Additionally, custom designs or specialized coatings can increase prices. Maintenance and replacement costs further add to the overall expenditure, making cost-effectiveness a key consideration in their selection and use.

7.3 Maintenance Requirements

Regular cleaning and lubrication are essential to prevent wear and ensure smooth operation. Inspect guide pins for damage or misalignment, addressing issues promptly to avoid downtime. Proper storage in a dry, protected environment prevents corrosion. Neglecting maintenance can lead to premature wear, misalignment, and reduced performance, emphasizing the importance of consistent upkeep for longevity and reliability.

Future Trends in Guide Pins

Future trends include the development of smart guide pins with IoT integration, advanced materials for enhanced durability, and improved precision through innovative manufacturing techniques and technologies.

8.1 Development of Smart Guide Pins

Smart guide pins integrate IoT technology, enabling real-time monitoring and adaptive alignment. These pins use sensors to detect positional changes, optimizing accuracy in dynamic environments. Advanced materials enhance durability, while energy-efficient designs reduce environmental impact. This innovation revolutionizes industries by improving automation, reducing downtime, and ensuring precise, reliable performance in high-tech manufacturing and engineering applications.

8.2 Integration with IoT Technology

Integrating guide pins with IoT technology enhances real-time monitoring and automation. Smart guide pins can communicate with manufacturing systems, enabling predictive maintenance and reducing operational downtime. IoT connectivity allows for remote tracking of alignment accuracy, ensuring optimal performance in smart manufacturing environments. This integration boosts efficiency, improves decision-making, and supports Industry 4.0 initiatives by enabling seamless data exchange.

8.3 Use of Advanced Materials

The use of advanced materials in guide pins, such as titanium and carbon fiber, enhances durability and performance. These materials offer superior strength-to-weight ratios, corrosion resistance, and thermal stability, making them ideal for high-performance applications. Advanced materials enable guide pins to withstand extreme conditions, ensuring longevity and reliability in demanding industrial environments while maintaining precision and alignment accuracy.

Selection Criteria for Guide Pins

Selecting guide pins involves evaluating load-bearing capacity, tolerance levels, and environmental factors. Material durability and alignment precision are critical to ensure optimal performance and longevity in specific applications.

9.1 Load Bearing Capacity

Load-bearing capacity is a critical factor in selecting guide pins, ensuring they can withstand the forces applied during operations without deformation. Higher capacity pins are essential for heavy-duty applications, while lighter loads may suffice for less demanding tasks. Material strength and pin diameter are key determinants of this capacity, influencing overall performance and reliability.

9.2 Tolerance Levels

Tolerance levels in guide pins refer to the acceptable range of dimensional deviation, ensuring precise fit and alignment. Tighter tolerances enhance accuracy but may increase costs. Proper tolerance selection balances precision needs with manufacturing practicality, as even minor deviations can affect overall performance and reliability in critical applications.

9.3 Environmental Factors

Environmental factors such as temperature, humidity, and exposure to corrosive substances significantly impact guide pin performance. Harsh conditions can lead to degradation or corrosion, affecting alignment accuracy. Selecting pins made from resistant materials or applying protective coatings can mitigate these effects, ensuring long-term reliability in diverse operating environments and extreme conditions.

Maintenance and Care

Regular cleaning and lubrication are crucial to maintain guide pin functionality. Proper storage in a dry environment prevents rust, ensuring longevity and optimal performance over time.

10.1 Cleaning Practices

Guide pins require regular cleaning to remove dirt, oil, and debris. Use solvents or ultrasonic cleaners for thorough cleaning. Avoid abrasive materials that may scratch surfaces. Gently brush away particles with soft-bristled tools. Ensure pins are dry before storage to prevent rust. Cleanliness ensures proper fit and functionality, maintaining precision and longevity.

10.2 Lubrication Requirements

Guide pins benefit from periodic lubrication to reduce friction and wear. Apply silicone-based sprays or oil-based lubricants to the pin surfaces or surrounding areas. Re-lubricate after cleaning or when operational noise increases. Avoid over-lubrication to prevent dirt accumulation. Proper lubrication ensures smooth operation, prevents corrosion, and extends the lifespan of the guide pins in industrial applications.

10.3 Storage Recommendations

Store guide pins in a clean, dry environment to prevent rust and contamination. Use protective packaging or cases to avoid damage. Keep them away from direct sunlight and moisture. Organize pins by size and type for easy access. Ensure storage areas are climate-controlled to maintain optimal conditions. Proper storage extends the lifespan and functionality of guide pins.

Safety Considerations

Handle guide pins with care to avoid injuries. Use proper tools for installation and removal. Wear protective gear like gloves and safety glasses. Follow manufacturer guidelines for safe usage and maintenance to ensure operational safety and prevent accidents.

11.1 Handling Precautions

Always handle guide pins with care to prevent damage or injury. Wear protective gloves and eyewear. Ensure pins are clean and free from contaminants. Avoid using pins as load-bearing devices. Store them properly to prevent corrosion or bending. Regularly inspect for wear and tear. Never force a pin into a misaligned hole to maintain precision and safety.

11.2 Safety Standards

Adhere to industry safety standards when using guide pins to ensure safe operations. Ensure pins meet material and dimensional specifications. Regular inspections are crucial to identify wear or damage. Follow load limits to prevent pin failure. Proper training on handling and installation is essential. Compliance with safety standards protects both workers and equipment from potential hazards.

11.3 Emergency Procedures

In emergencies involving guide pins, immediately halt machinery to prevent further damage. Assess the issue, such as a broken or misaligned pin. Use appropriate tools and safety gear to correct the problem. Document the incident and conduct a root cause analysis to avoid future occurrences, ensuring workplace safety and machine integrity.

Guide pins are essential tools in manufacturing, ensuring precise alignment and stability. Their versatility across industries highlights their enduring importance. As technology advances, guide pins will continue to evolve, maintaining their critical role in driving efficiency and accuracy.

12.1 Summary of Key Points

Guide pins are crucial for ensuring precise alignment and stability in manufacturing processes. Available in various types and materials, they cater to specific industrial needs. Proper installation and maintenance are essential for optimal performance. Their versatility and adaptability make them indispensable in industries like aerospace and automotive manufacturing, driving efficiency and accuracy.

12.2 Final Thoughts on Guide Pins

Guide pins are indispensable in modern manufacturing, offering precise alignment and stability. Their versatility across industries like aerospace and automotive underscores their importance. As technology evolves, advancements in materials and smart designs will further enhance their role. Balancing cost, durability, and precision remains key to their continued effectiveness in driving industrial efficiency and innovation.